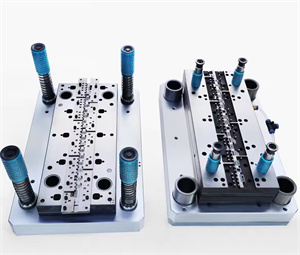

Progressive molds play an important role in the manufacturing of automotive components. Automotive components typically have complex shapes and high precision requirements, which can be met by progressive molds. It can complete multiple processes in a continuous stamping process, thereby efficiently producing various automotive components. For example, the body structural components of a car, such as the inner panels of the car door and hood, can be formed into complex shapes through progressive die stamping, while ensuring the dimensional accuracy and consistency of the parts.

For some small automotive components, such as connectors, terminals, etc., progressive molds can be produced quickly and in large quantities, improving production efficiency and reducing costs.

In addition, the chassis and seat components of automobiles can also be produced using progressive dies for stamping. The use of progressive molds makes the production of automotive components more efficient, precise, and stable, which helps to improve the overall quality and performance of automobiles.

Auto parts suitable for progressive die stamping usually have the following characteristics:

1. Large batch size: Progressive die stamping mold is suitable for mass production, because it can complete multiple processes in one mold, which significantly improves production efficiency.

2. Complex shape: For stamping parts with complex shapes that require multiple processes to complete, progressive die stamping is a good choice. It can complete a variety of operations such as blanking, bending, forming and drawing in one mold, avoiding the trouble of changing the mold multiple times.

3. High precision requirements: Due to the use of high-precision mold design and manufacturing technology, the accuracy and quality of stamping parts can be ensured. For some stamping parts that require high precision, progressive die stamping is a good solution.

Progressive die stamping are suitable for the production of stamping parts in large quantities, complex shapes, high precision requirements and a wide range of materials. However, the use of progressive die stamping molds also needs to be considered according to the specific production needs, technical level and cost budget. In practical applications, it is necessary to select the appropriate die type and processing method according to the characteristics and requirements of the stamping parts.