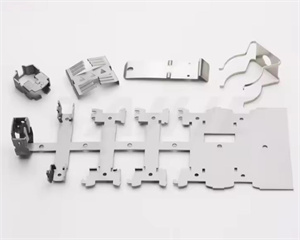

Progressive Die Stamping is an efficient stamping process that typically involves multiple stations, each performing a different machining operation, and the stations are sequentially linked to each other. For Progressive Die Stamping, the choice of material is crucial as it directly affects the accuracy, performance, productivity and cost of the stamped part.

Here are some of the materials commonly used in Progressive Die Stamping:

Stainless Steel: Stainless steel is a common material for Progressive Die stamping due to its excellent corrosion resistance and strength. It is able to withstand the complex stresses of the continuous stamping process in multiple stations and maintain stable forming performance, especially for applications that require long-term accuracy and stability.

Carbon steel: Carbon steel has good strength and toughness, and the cost is relatively low, so it is widely used in Progressive Die Stamping. By adjusting the carbon content and heat treatment process, different levels of hardness and toughness can be obtained to meet the needs of different stamping parts.

Aluminum alloy: Aluminum alloy has light weight, high strength and good formability, which is suitable for Progressive Die Shaping parts that need to reduce weight while maintaining high accuracy. In aerospace, automobile manufacturing and other fields, aluminum alloy is particularly widely used.

Copper and copper alloys, such as brass, phosphor bronze, etc., are also commonly used in Progressive Die Stamping. These materials have good electrical conductivity, thermal conductivity and formability, and are suitable for the manufacture of stamping parts in the fields of electrical and electronic fields.

Special alloys: For specific applications, special alloys with properties such as high temperature resistance, corrosion resistance or high strength may be required. These alloys are able to meet the performance requirements of Progressive Die Stamping in complex operating environments.

Low carbon steel: It has good plasticity and machinability, relatively low price, and is commonly used to manufacture general stamped parts.

High strength steel: such as high-strength low alloy steel, suitable for components that withstand large loads and impacts.

In automotive manufacturing, progressive die stamping is commonly used to produce body panels, which may use low carbon steel or high-strength steel; In the manufacturing of electronic device casings, aluminum alloy may be a more common choice.