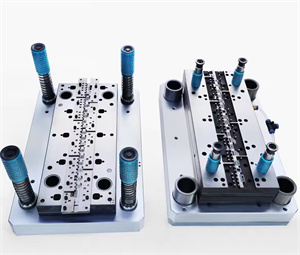

Progressive metal stamping can improves productivity by auto multiple steps including stamping, blanking, piercing and forming. Our progressive die stamping could up to 300 strokes per minute. fulfilling complex, high volume stamping orders for the electronics, automotive, medical and aerospace markets.

Progressive metal stamping die can complete blanking, bending, forming, drawing and other processes. Each stroke of the press can punch a workpiece or process piece, so it has higher labor productivity.

Progressive die stamping die with strip stamping raw materials and several different positions on one die to complete multiple stamping processes at the same time. Each time the die is finished, the strip moves once at a fixed distance until the product is finished.

A progressive stamping, also known as a progressive die, is a type of stamping die that is capable of completing multiple stamping operations sequentially during the stamping process. The design of this die can make the stamping parts complete a plurality of punching, step punching, forming, stretching, flanging, trimming, punching and other actions in a continuous stamping process, so as to obtain the required stamping parts.

The structure of progressive die stamping is relatively complex, but the production efficiency is high, and it is suitable for mass production of stamping parts. Compared with single dies, progressive die have less punching force, but the manufacturing cost of the dies is higher. In addition, the way the Progressive stamping is fed and scrap removed is unique.

There are two main feeding methods for progressive stamping: coil feeding and sheet feeding. Coil feeding is to send coiled sheets to the die through the feeder for stamping, which is suitable for the production of long length stamping parts. Sheet feeding is to send the cut sheet metal to the die for stamping through manual or automatic feeding mechanism, which is suitable for the production of short stamping parts.

There are two main ways to remove scrap from progressive die stamping: natural stripping and forced stripping. Natural stripping is to use the structural characteristics of the stamping parts themselves to make the waste material fall off naturally during the stamping process. Forced stripping is to forcibly discharge the waste from the mold through the ejection mechanism or suction cup and other devices in the mold.

Progressive die is an efficient and accurate stamping die suitable for high-volume production of stamping parts. It has a complex structure, but it is capable of continuous operation of multiple stamping processes, thereby improving production efficiency and product quality.

Material of Progressive metal stamping:

Spring steel, stainless steel, brass, nickel alloy, phosphor bronze, ect.

Equipment of Progressive stamping:

Stamping press.

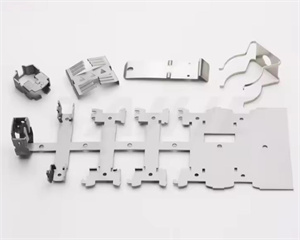

Application of Progressive stamping:

Electrical contacts, battery connectors, mobile electronic components, fixture retainers, led lighting, ect.